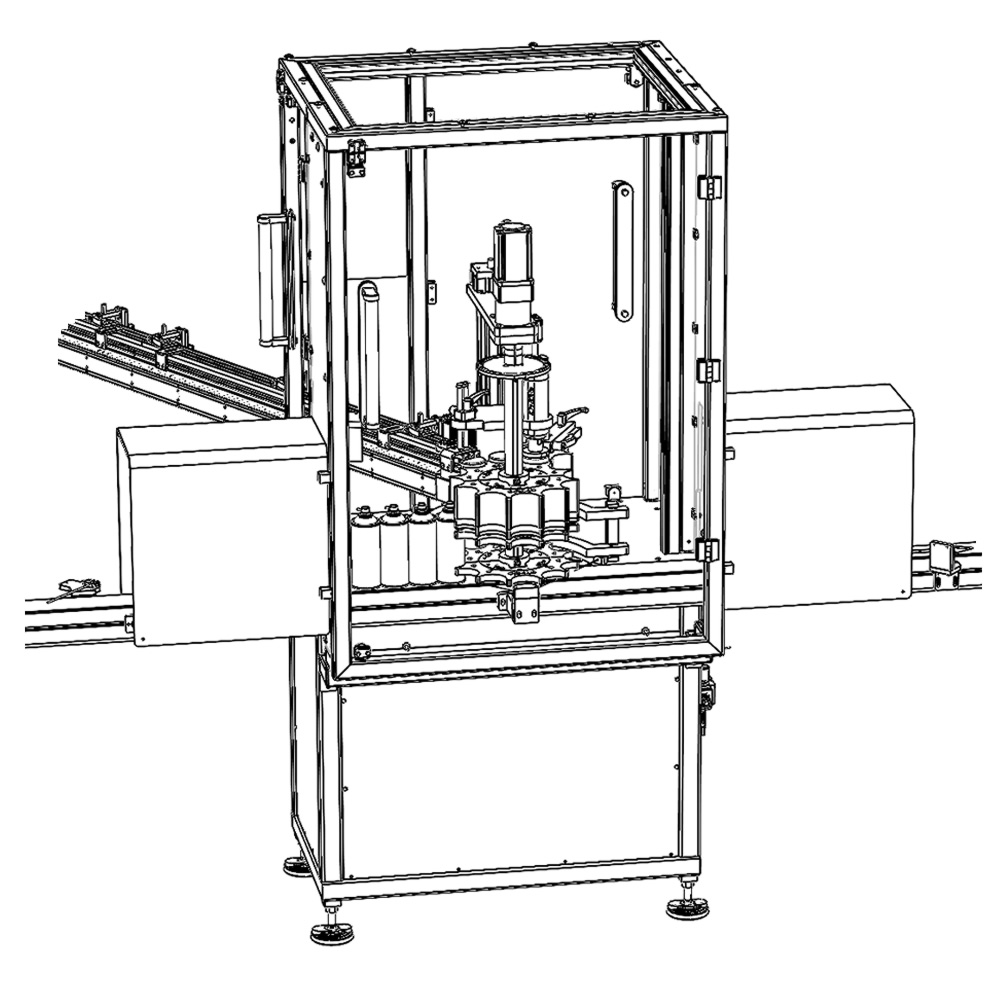

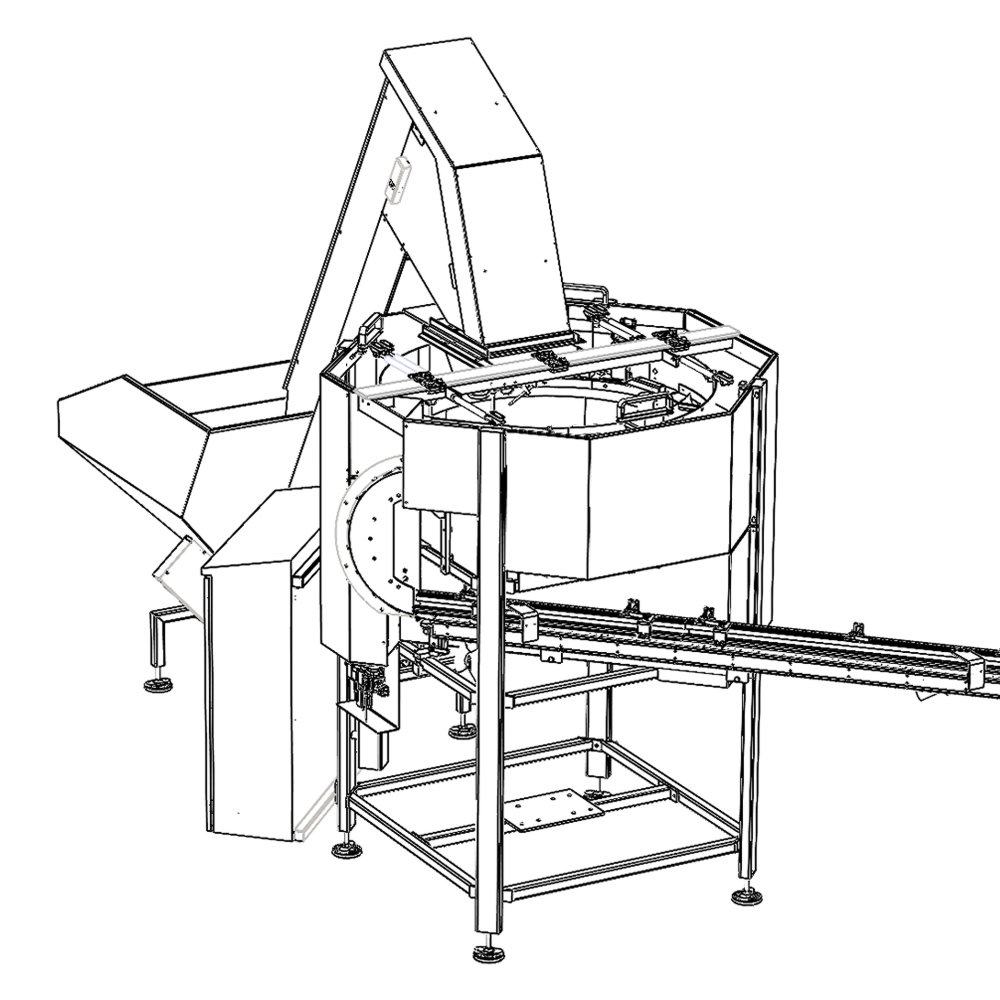

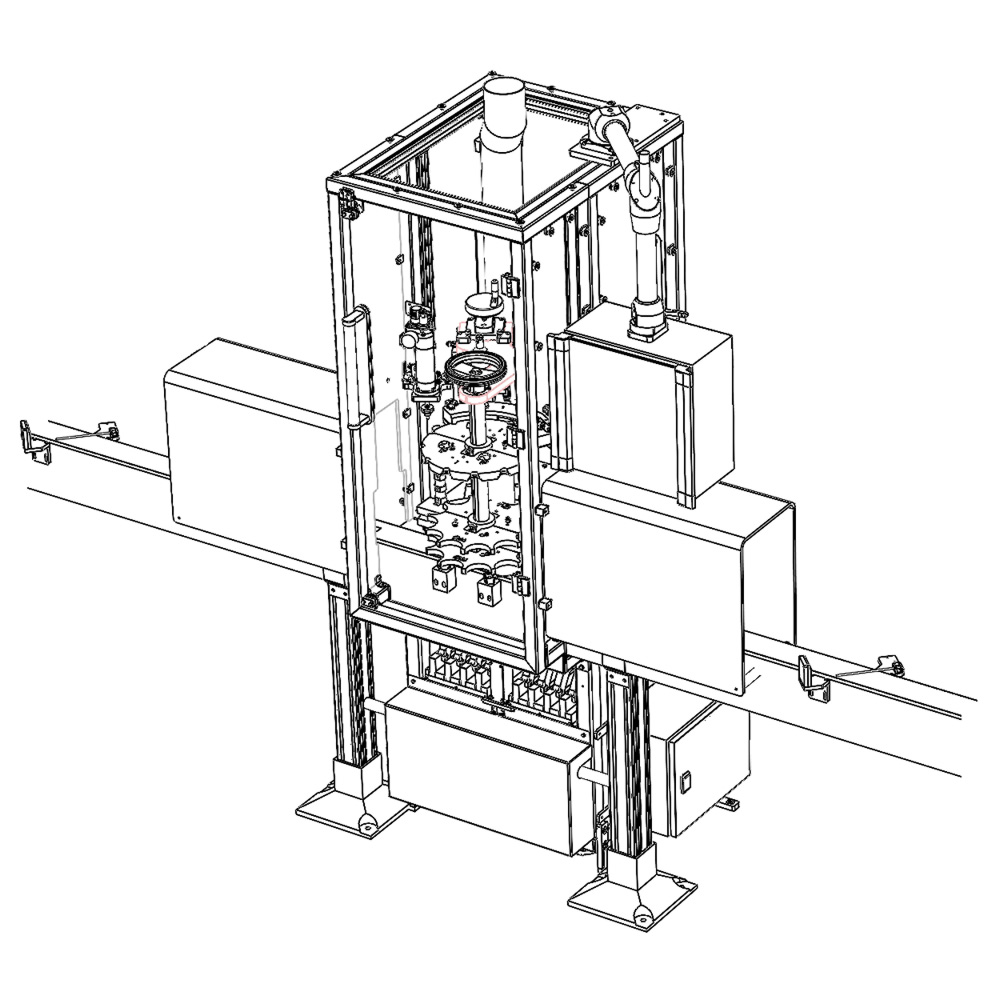

Inserting / Placing of Spray Nozzles / Heads |

|

|

|

The basis of the system is a servo-controlled star- wheel. With the star-wheel, the aerosols are transported to the press position where the spray heads / nozzles, with a speed of up to 120 products per minute, are placed on the aerosols. The system will be completely built suitable for your products. Optional, the installation can be built for several product types / versions. This also applies to the feeder system. The system can be designed in such a way that it connects to your current transport system. We can also take care of the in- and outfeed transport of the aerosol cans. |

|